ELV Drainage and de-pollution – All fluids are removed – fluid de-pollution

The de-pollution of used vehicles includes equipment and systems for the complete removal of liquids such as gasoline and diesel, waste oil, coolant, brake fluid and coolant but also LPG and UREA. The systems are continuously developed and perfected. From site planning to individual systems and service – SEDA is your partner.

Devices can be used independently or as part of plants or systems. For each liquid there is the appropriate device. Vehicle racks allow you to process the cars from below. There are several platforms, lifts or rigid vehicle racks. Mobile systems can always be relocated to adjust the operating conditions and are an alternative where fixed installations are not desired. Stationary systems are permanently mounted and tailor made. The preinstalled systems are ready for immediate operation. The accessories include various components that make de-pollution easier.

SEDA Tank Drilling Machine HD Type Truck V19

Due to the extremely low construction it is suitable for very low hanging tanks (21 cm floor clearance still offers enough space fluid removal). The [...]

SEDA TankDrillingMachine GreenPoint DUO

GreenPoint is the a SEDA product line with original, high quality SEDA products like the TankDrillingMachine for small enterprises.

SEDA Tank Emptying Device

The individual components of the system are each designed in such a way that they form a closed system. This applies to the corresponding media as we [...]

SEDA E-CAR Recycling Station

A QUALIFIED ELECTRICIAN WITH HIGH-VOLTAGE TRAINING is required to work on the lithium-ion batteries! More information Technical details Compresse [...]

SEDA ModuleTwo

1st column (fuels) with air processing unit and a tank drilling machine on swing arm with new fuel switch, 2 x V25 double diaphragm pumps for petrol [...]

SEDA Single Column Lift 3.5

The hydraulic SingleLiftingRamp 3.5 of SEDA lifts vehicles up to 3.5 tons.

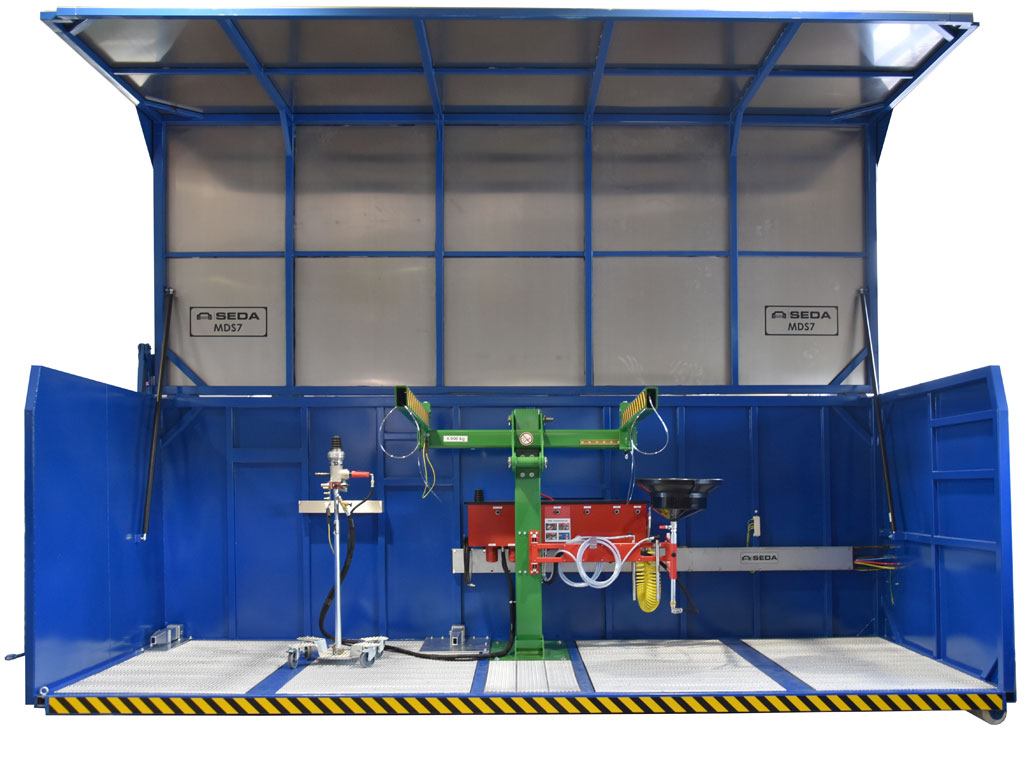

SEDA MDS7 Container DrainBox

The SEDA MDS6 Container VehicleRamp is a roll-off container in which a complete drainage system is integrated. The opened container cover functions l [...]

SEDA MDS6 Container VehicleRamp

The SEDA MDS6 Container VehicleRamp is a roll-off container in which a complete drainage system is integrated. The opened container cover functions l [...]

SEDA MDS2 Plattform JumboLine

SEDA MDS2 Platform JumboLine: mobile scrap car drainage system with platform and vehicle ramp SEDA JumboTower: stationary scrap car drainage system w [...]

SEDA MDS2 Platform TL-2

It is easy to place a car with a forklift on the system. Than a hydraulic safety arm fixes the vehicle. The fixing arm can be adapted by various opti [...]

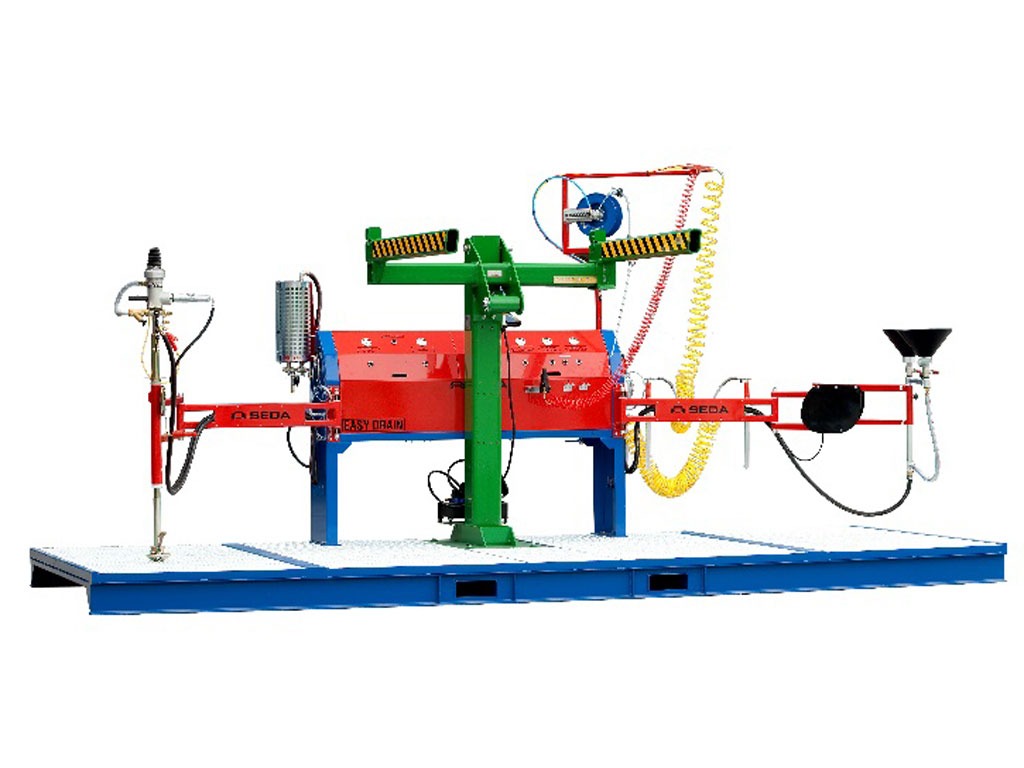

SEDA MDS2 Platform EasyDrain

SEDA’s MDS series offers many opportunities - universally applicable, flexible location and efficient de-pollution of end-of-life vehicles. More in [...]

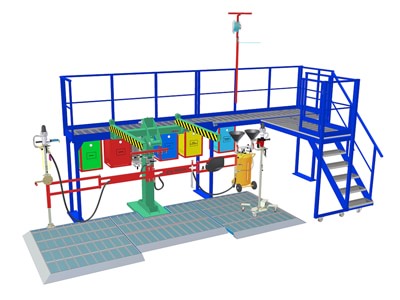

SEDA WorkingPlatform

An easily movable and adjustable staircase reduces the risk of falling and ensures that vehicles of all sizes can be drained at the SEDA WorkingPlatform.

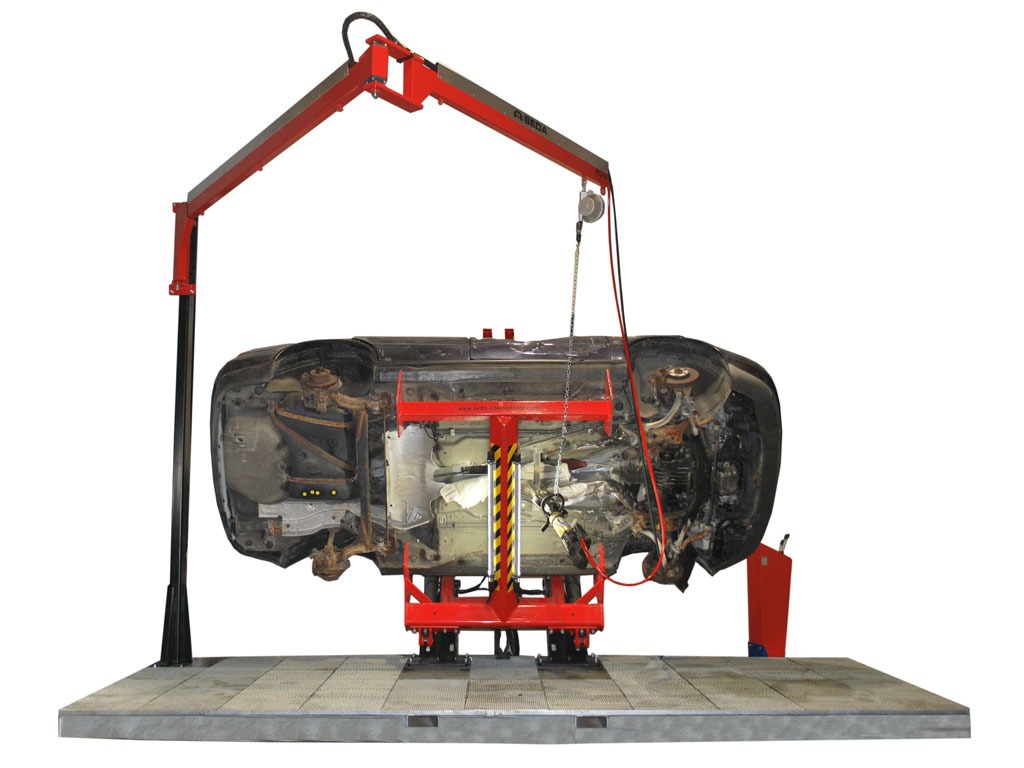

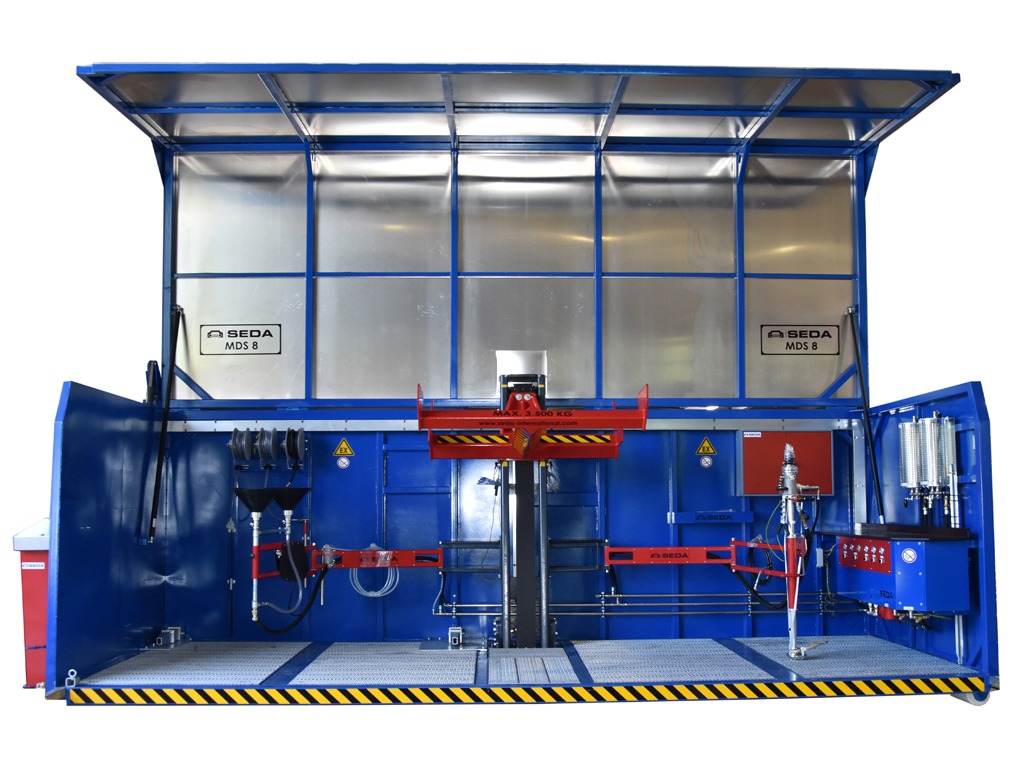

SEDA MDS8 Container DrainLift

Also simple dismantling work can be done on it hassle-free. More Information Technical details Lifting height: up to 1800 mm Overall height: 241 [...]

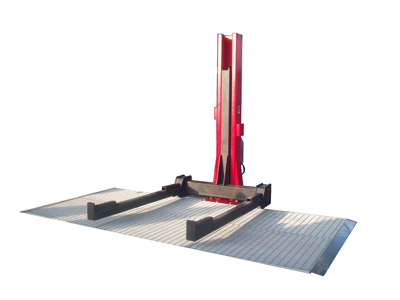

SEDA MDS2 Platform DrainLift

The SEDA MDS2 Plattform DrainLift is the ideal combination of a single hydraulic lift with the tried and tested SEDA drainage system, situated on a mobile platform.

SEDA DrainLift Start

The SEDA DrainLift is the ideal combination of a single hydraulic lift with the tried and tested SEDA drainage system.

SEDA Oilfilter Caps

The SEDA oil filter caps are used to prevent leaking residual oil from the end-of-life vehicle.

SEDA OilSeparator

SEDA oil separators provides filter-less technique which combines numerous advantages. Intelligent detail solutions as well as a sophisticated and flexible technology will enable the operators a reliable, simple and safe operation and to save operating costs at the same time.

SEDA DrainBox

The DrainBox fulfills requirements with its compact size for the needs of small recyclers and fits perfectly into existing processes and automations. [...]

SEDA TruckStation Mobile

For trucks, buses and other heavy vehicles SEDA developed a new solution, designed specifically for junkyard operators.

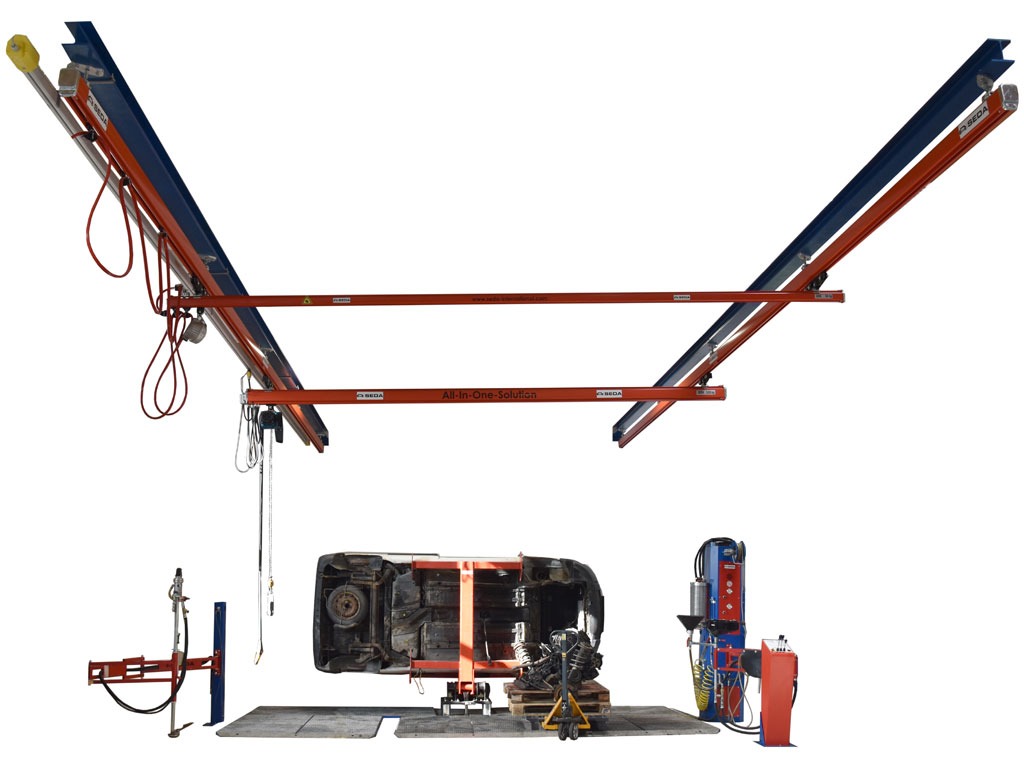

SEDA All-In-One Solution

The SEDA All-in-One Solution is the first complete system for ELV de-pollution and dismantling.

SEDA AC Remover

The new SEDA AC Remover is used for simple and efficient degassing of automotive air conditioning in cars, trucks and buses.

SEDA VehicleTrolley V18

The new SEDA VehicleTrolley TL is specially adapted to the SEDA TiltingLifts and allows forklift-free maneuvering.

SEDA ModuleOne START

The ModuleOne START ist the compact and professional ELV de-pollution solution for low volume dismantlers!

SEDA SinglePostLift 3.5

The hydraulic SingleLiftingRamp 3.5 of SEDA lifts vehicles up to 3.5 tons.

SEDA SOG2

The 4 shock absorbers from a vehicle can contain up to 1.5 liters of oil which must be drained by the SOG2.

SEDA TankDrillingMachine GreenPoint

GreenPoint is the a SEDA product line with original, high quality SEDA products like the TankDrillingMachine for small enterprises.

SEDA VehicleRamp

The SEDA VehicleRamp is a steel construction for the perfect mounting of vehicles.

SEDA FuelVacuumKuli

The successful SEDA FuelVacuumKuli (petrol and diesel) is the perfect solution for emptying tanks of vehicles like cars or motorbikes.

SEDA GearboxDrillingMachine

The SEDA GearboxDrillingMachine removes waste oil by drilling into the oil casings or pans.

SEDA 4-Fluid Station

The 4-Fluid Station is a compact and mobile entry-level solution for smaller dismantlers with a de-pollution rate of up to 5 vehicles per day.

SEDA VehicleTiltingRamp

Dismantling companies need equipment which support their work process. The SEDA VehicleDismantlingPlatform moves the car, not the worker.

SEDA Fuelmanager

The new SEDA FuelManager is the optimal solution for decontaminating otherwise potentially useless rusty, oily or moisture rich fuel into valuable fuel.

SEDA TruckStation ED

Fully equipped with powerful pumps, special hoses and supplies, the SEDA TruckStation ED meets the special requirements for the de-pollution of trucks.

SEDA MDS2 Platform

The SEDA’s MDS2 Platform and the whole MDS series (mobile drainage systems) offer many opportunities for car dismantlers.

SEDA Tankplattform TPF5

Equipped with 5 storage tanks the new SEDA TPF5 platform offers everything that is needed for the collecting of fluids of End-of-Life vehicles (ELV).

SEDA JumboTower

Stationary scrap car drainage system with vehicle ramp.

SEDA TruckStation ED-G

Dismantling of trucks, buses or other heavy vehicles are increasingly important for recyclers worldwide. SEDA offers a good solution with TruckStation ED-G.

SEDA TankDrillingMachine

More than 20 years and used by 3.000 dismantlers the robust SEDA TankDrillingMachine has entrenched itself as the industries favourite ELV drainage device.

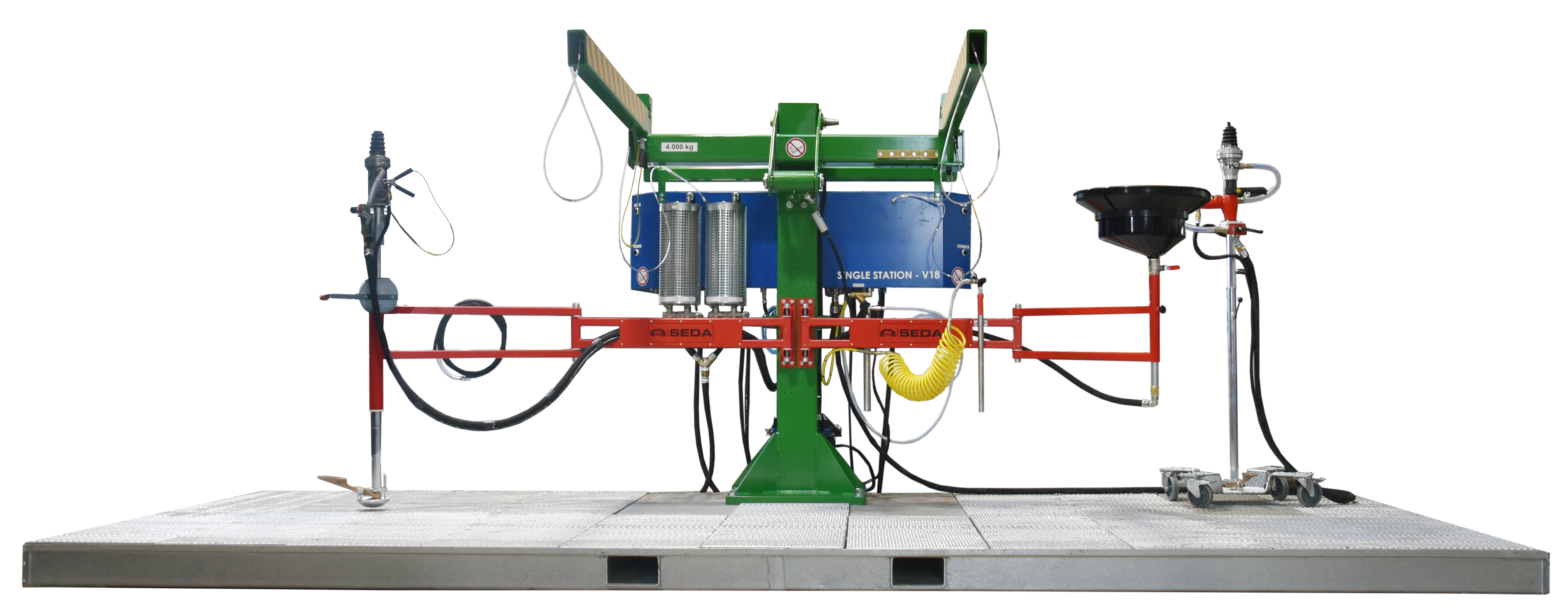

SEDA SingleStation

The SEDA SingleStation is the most advanced and efficient end-of-life vehicle (ELV) drainage system on the market.

SEDA Rapid

The SEDA Rapid is a simple, modern and flexible station designed for mid-size dismantlers.

SEDA ModuleOne

The ModuleOne is easy to install, has a small footprint with SEDA built quality at an affordable price.

SEDA DrainTower

The SEDA DrainTower combines proven SEDA technology with an efficient design concept.

SEDA EasyDrain

The SEDA EasyDrain is an ideal solution to drain all fluids from End-of-life vehicles (ELV).

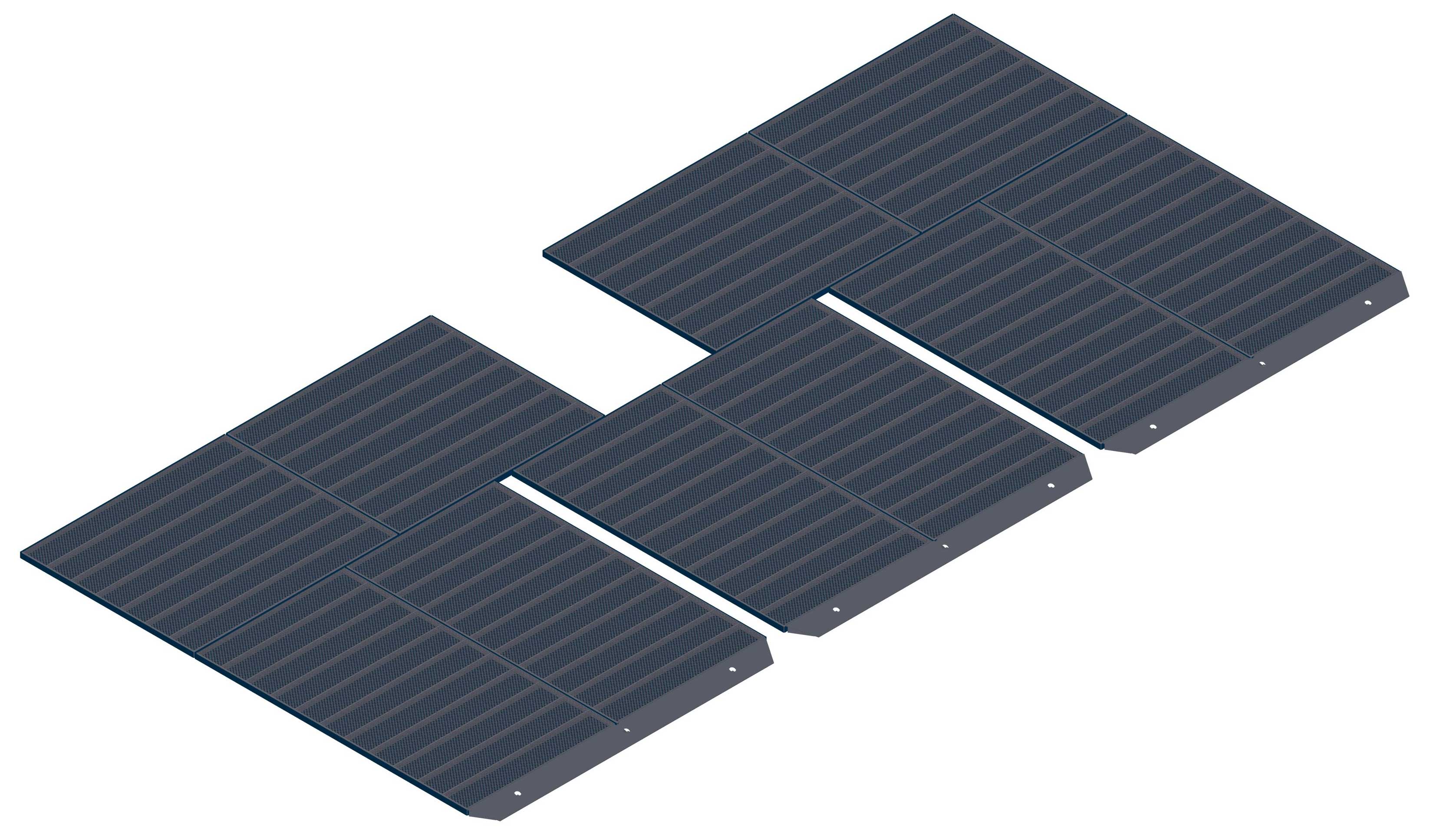

SEDA Recycling Line

Re-source Engineering Solutions and SEDA developed a complete solution for plant facilities: The Recycling Line

SEDA LPG Recovery CLASS

SEDA’s LPG Recovery System CLASS is the easiest way to remove and store LPG and neutralize LPG tanks from End-of-Live Vehicles (ELV) automatically.

SEDA LPG Recovery ECO

The LPG Recovery ECO is used to extract the LPG in LPG vehicles.

SEDA Natural Gas Torch

Natural Gas burner for flaring of natural gas.

SEDA Gas Torch

Gas burner for flaring of gas and liquid phase with special design for draining LPG vehicle tanks.

SEDA Mobile

The SEDA Mobile represents the most efficient, cost effective and reliable solution for draining all fluids from „End of Life“ vehicles in a mobile way.

SEDA MotoRecyclingSystem

SEDA MRS (MotoRecyclingSystem) is the first equipment for the de-pollution of motorbikes.

SEDA MotoServiceLift

The SEDA MotoServiceLift (MSL) is a specially developed lifting device for motorbikes.

SEDA HoseGun HD

To remove hydraulic oil from hoses or pipes effectively, a powerful tool is needed. The SEDA HoseGun HD is the perfect solution.

SEDA Catchment Area

SEDA offers different types of catchment areas for its drainage stations.

SEDA Compressors

SEDA offers three types of compressors.

SEDA StorageTanks

SEDA storagetanks offers the ideal solution for the safe and easy storage and disposal of heating oil or diesels.

SEDA TiltingLift TL-1 600 & TiltingLift TL-1 1800

The SEDA TiltingLift TL-1 600 & SEDA TiltingLift TL-1 1800 are further developments of the SEDA TiltingRamp with a special lifting feature.

SEDA OilFilterCap

The SEDA Oil Filter Cap is an universal product and offers an easy and intelligent solution for a safe and tight seal for removed oil filters.

SEDA SuctionLance

The SEDA SuctionLance guarantees a complete suction of the windscreen wiper fluid from the reservoir.

SEDA Spotlight

EX-proofed spots for an optimal illumination of your working space.

SEDA BrakePipePliers

If a break nipple tears off or is damaged and an opening is impossible, the SEDA BrakePipePliers (for metal pipes) can be used instead.

SEDA BrakeHosePliers

If a break nipple tears off or is damaged and an opening is impossible, the SEDA Brake Pipe Pliers (for metal pipes) or the Brake Hose Pliers (for rubber hoses) can be used instead.

SEDA Overfill protection

Complete Solution (Power supply and lines to the tanks are needed). From 1 up to 5 tanks.

SEDA FlameArrestor

Approved as an in-line flame arrestor (EN ISO 16852), it absorbs the heat of a flame by quenching the temperature below ignition point, preventing a flash-back of potentially explosive vapor-air and/or gas-air mixtures.

SEDA WindshieldWashwaterFilter

By using this filter results in a resale possibility of the purified water. The 3/4“-‐Filter can be integrated by easy installation in existing systems.

SEDA JumboLine

This vehicle rack is part of the SEDA Jumboline series. It is very robust and made for big cars in particular.

SEDA Urea Suction Device

According to the european ELV-Directive, all liquids must be removed from the vehicle during the recycling process. This includes urea (AdBlue).

SEDA JumboLine MDS2

The SEDA JumboLine MDS2 is a mobile scrap car drainage system with platform and vehicle ramp.

SEDA TiltingLift TL-2 1800

The SEDA TiltingLift 1800 O-F is a further development of the SEDA TiltingRamp with a special overfloor lifting feature.