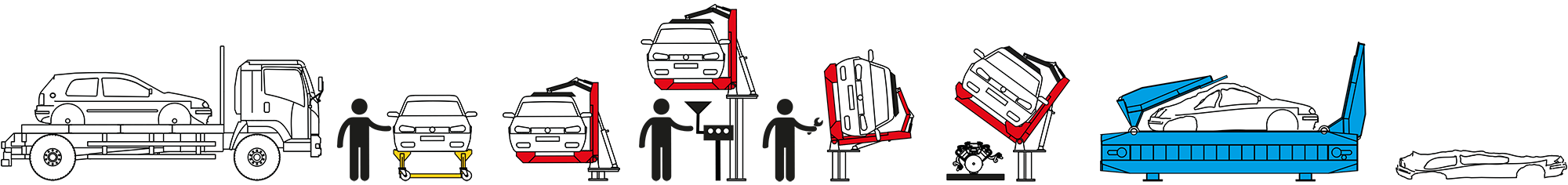

SEDA Umwelttechnik GmbH – the global market leader in car recycling technologies, together with BDSV (the Confederation of German Steel Recycling and Waste Management Companies) carried out a perfect showcase of car and e-car recycling at IFAT 2022. International visitors and professionals from all over the world could experience the entire recycling process performed live on the exhibition area of 3,586 m². SEDA went so far as 3 times a day to demonstrate the complex 7-stage car recycling process on seven spots within the booth. To polish the visitor’s practical skills, SEDA provided exhaustive information encompassing the current and related innovative processes as well as handling of ELVs. The industry gurus and SEDA expert team answered numerous questions and provided new solutions for recycling companies.

IFAT 2022 in Figures

More than 119,000 visitors from over 160 countries came to Munich to take part in the International Trade Show from the 30th of May to the 3rd of June, 2022. A total of 2,984 exhibitors presented their products and innovations for the booming environmental industry.

IFAT Munich is the world’s largest leading trade fair for the environmental technology issues. Every two years, the world’s leading trade fair presents solutions in such areas as water treatment, sewage, waste and raw material management as well as strategies for using resources in intelligent cycles and sustainable ways. Next IFAT Show will take place from the 13th to the 17th of May, 2024 at the exhibition centre in Munich.

More info: www.ifat.de

Car Recycling – Video

01 Storage

The 1st Step implies efficient and ergonomic storage of the vehicles. It is absolutely clear that compact storage of ELVs (storage racks) – especially in case of limited workshop space, accounts for order and tidiness in accordance with the EU guidelines and makes it easier to streamline the procedures. The warehouse management (EDP-based) enables a direct access to each vehicle.

02 Preparation

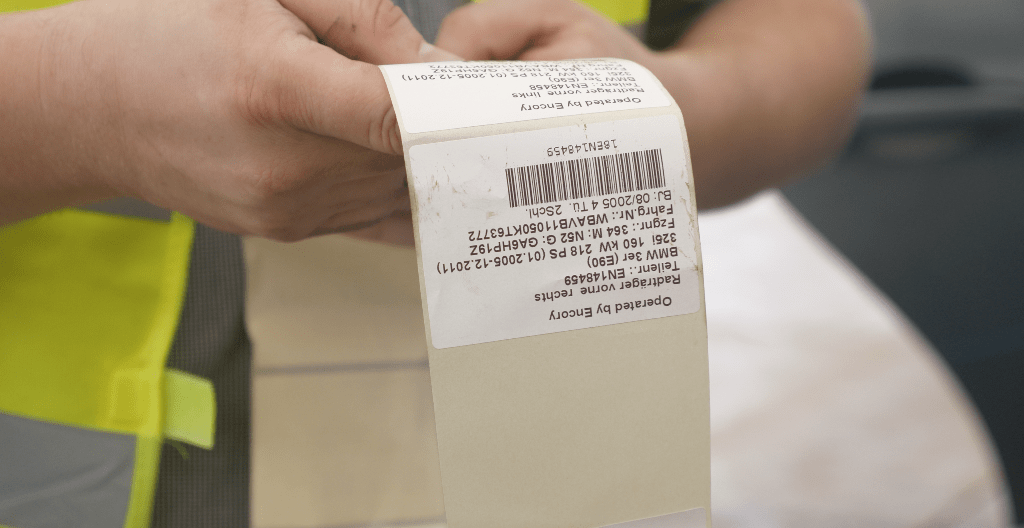

Once a vehicle has been selected for recycling, its preparation starts according to the data in the EDP-system. We work out a disassembly and dismantling plan for the parts that can be prepared for further sale and use. All the other parts get into the raw material recycling process. There are two ways a car part may be handled – either resale or raw material recycling.

Dismantling is launched on a so-called vehicle trolley. This mobile trolley provides an easy positioning of an ELV in the workshop without a forklift. The model of a forklift-free workshop has been very popular in the recycling industry, since the maintenance costs are low and possible dangers of forklift operating are eliminated.

Heavy metals and potential sources of inflammation are removed from the vehicle. At first, it is urgent to dismantle the battery and, if necessary, suck the LPG/CNG gas out. The explosive car parts that should by no means end up in the shredder, such as the pyrotechnic gas generators of the airbags, are removed or neutralized in the vehicle. Once an airbag is removed, it is stored in a special transportation box for dangerous goods. If the seats and items of the car interior are not going to be sold, a quick and easy way to neutralize the airbags is immediately inside the vehicle. For that a SEDA Multiplex device, which is connected to the airbag control unit, is used. Light detonations are caused by the belt tensioners. Strong detonations are to be expected from the front and side airbags. Removed airbag systems are dangerous, therefore special restrictions and certain responsibilities in terms of storage and transportation rest with a car recycler. With the help of SEDA airbag cabin (ANC) we can neutralize airbags safely and soundly. After the procedure has been accomplished, there are no special requirements for storage, transportation or disposal any more.

Then the windows are smashed and we get all the shards into a special glass trolley. We have now stripped the carcass of the first batch of raw materials and now it is ready for an agile dismantling. Further preparatory work steps include depolluting the liquids from the upper engine compartment, sucking the climate gas with the AC Remover (ACR) and taking off the wheels. The T-REC XXL press enables a quick separation of tires and wheel rims (suitable for 13–22-inch rims).

03 Depollution

At this stage the vehicle is prepared for depollution. On average, there are 22 liters of liquid in an end-of-life vehicle.

Now it is the turn of the new DrainLift Professional system, which is explosion-proof in accordance with ATEX. It consists of a hydraulic single-column platform with all the necessary tools for draining. Such a professional system enables a vehicle to be completely depolluted in just a few minutes.

The tank is drilled with a special Fuel Tank Drilling Device, which immediately sucks the fuel out of the tanks. Upon visual inspection, the fuel is flown into the corresponding tank on a mobile tank platform. After that, special hoses are connected to the brake nipples and the brake fluid is depolluted with the help of one of the extra vacuum pumps. Two suction lances are used to pierce the container with the windscreen cleaning fluid and the coolant and they suck up these liquids. It means that all the processes run simultaneously and enable quick, safe and environmentally-friendly depollution of an end-of-life vehicle

04 Dismantling

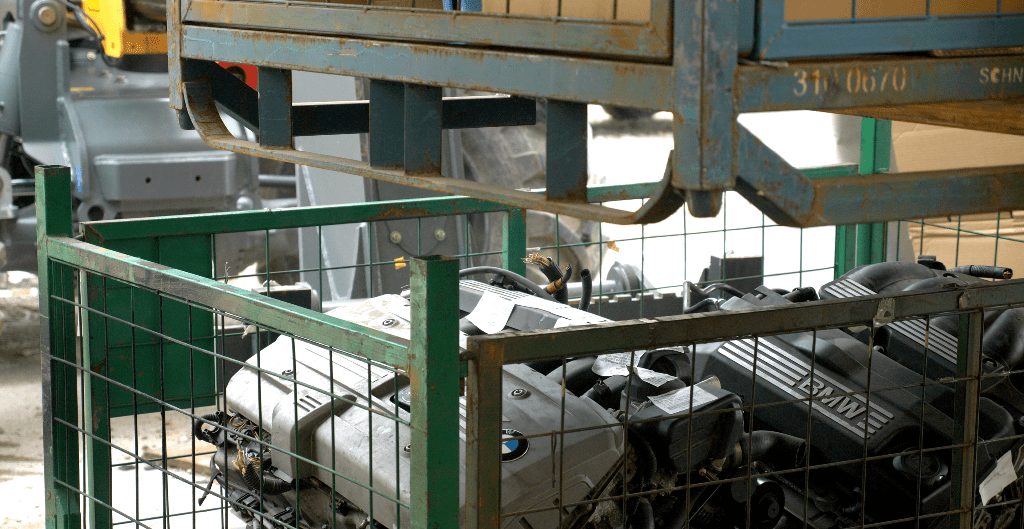

Step 4 starts with pushing an end-of-life vehicle on a trolley to the next station for dismantling. The list of parts that are going to be dismantled has already been compiled at the initial stage. And that is exactly the pivoting point for profitable business to start – up to 300 parts from an end-of-life vehicle can be resold!

A special steel frame construction called SEDA’s “All-in-One Solution” is used for dismantling. All previous work steps, such as preparation, depollution and dismantling can be performed here as well. Depending on the penetration level of dismantling, the entire process may take up 2-3 hours. The All-in-One is equipped with a tilting lifting platform, which makes it much easier to work on the underneath of a car. Heavy parts such as axles do not have to be dismantled overhead anymore. The All-in-One can be equipped with the tool set meeting customers’ exact requirements. We use hydraulic shears to cut a catalytic converter off the base and take it down. Containing rare constituents, a catalytic converter is a value-adding part gained from an end-of-life vehicle. With the crane lift operating at the top of the metal frame construction, such heavy parts as the rear axle can be easily handled while being dismantled and transported directly to a workbench. The advantage is that 2-3 mechanics can work there simultaneously.

05 E-Car Recycling

Electric cars occupy a special place in vehicle recycling. For instance, when an E-car had an accident and caught fire in the immediate vicinity of the SEDA headquarters in Austria three years ago, it made it absolutely clear how much unprepared the entire handling and recycling chain was for the proper disposal of an electric vehicle. At that very point SEDA came up with a solid concept and launched its innovative products for transportation, storage, dismantling and recycling of electric vehicles, which is actually based on three pillars:

1) Training

2) Equipment

3) Location

Risk management and high-voltage training for staff is of high priority for SEDA. Therefore, SEDA provides such special training courses for vehicle recyclers at its own e-car recycling centre in Kössen in cooperation with the Academy of the German Motor Trade. Practical courses take place 4 times a year (you will find our course planner here)

The condition of damaged vehicles is always pre-analysed by specially trained staff in terms of potential danger and, if necessary, those vehicles are kept in quarantine. The reason for it is that damaged batteries can self-ignite anytime long after the accident. As a rule, such quarantine lasts 72 hours before the vehicle processing can be resumed.

SEDA’s container Q-Tainer can be used for transportation of dangerous vehicles and as a quarantine area. The container prevents fire, if any, from spreading and the container can be cooled down. Toxic gases are kept inside and neutralized with the help of mineral filter technology.

To prevent fire spread when transporting a vehicle in a critical or non-analysed condition, SEDA also offers an ergonomic and patented solution for tow trucks and trailers. The safety fire-proof blanket is an integrated part of the trailer, which deals with possible sparks during transportation. This universal module can be tailored and inbuilt into any type of trailers or towing cars quickly and effortlessly. The safety fire-proof blanket is the best solution for towing service, fire brigades and car workshops.

At the very beginning of the processing of an electric vehicle, as long as the battery is still inside, the attention should be paid to the fact that only HV-trained specialists may proceed with the processing and only in a confined area. For safe dismantling a special set of HV-tools and protective equipment, such as insulating gloves and safety goggles, are indispensable, as we should never discard the idea that the battery may eventually turn out to be in a critical condition. Dismantling aims at the removal of the battery modules from the vehicle’s battery pack, their examination in order to determine if they can be used again or they have to be disposed of in the process of raw material recycling.

Here is SEDA E-Car Recycling Station: a 2-column lifting frame that is properly supported on the rims. It has especially been designed for the dismantling of large batteries, which may take up almost the whole space underneath the car and for which Tesla here is a vivid example. The first step is to switch off the power in the vehicle, meaning that a 12-volt battery has to be disconnected and the main switch turned off. Then the relays inside should open and the modules can be removed.

The battery is then dismantled from the vehicle and placed onto a special lifting table. A current Tesla battery with the biggest range weighs around 700 kg. SEDA offers pneumatic and manual lifting tables with a load capacity of up to 1,400 kg. The lifting table transfers the battery to the SEDA dismantling table with an integrated extinguishing pool under the work surface. The battery is pushed along the rollers of the work surface into the parking position. In case of danger the battery or its separate modules are immediately dumped into the extinguishing pool.

For the ideal storage, it is recommended to use a discharging device to perform partial or total discharging of the modules. Discharging of Li-Ion batteries is an important part of the recycling as it helps reduce the risks for its further handling. In addition, transport costs are reduced because of simplified legal requirements for transportation. After appropriate discharging, the batteries in a critical condition must be stored according to all safely requirements. The transportation of lithium ion batteries is a dangerous process, therefore a BAM approval of the transport box is required.

Here we show two variants for storage and transportation:

The SEDA Strainbox and the SEDA BAT-Box are both transportation and storage boxes with an integrated filtering system for lithium-ion batteries in a critical state. Should the batteries be damaged, the box will filter and neutralize toxic gases and prevent the escape of solid stuff, liquids and flame from the box. The integrated temperature management prevents any critical increase in temperature on the outer walls.

For the storage of large number of batteries, SEDA offers the HV battery container. A separate container has got 8 floodable compartments for defective batteries or for batteries with non-analyzed and non-determined dangers. If a battery reacts and the temperature in the container rises above 68°C, the nozzles open, water floods the compartment and further reaction of the cells is suppressed. An additional warning system (optional) enables remote monitoring of the battery temperature.

06 Further Handling

Various further processing steps are shown below. If the parts are suitable for sale, their photos should be uploaded on the internet (80-90% of the used parts are successfully traded via the internet).

Shredding of car parts and clean separation of shredded raw materials into categories is very urgent today, as a substantial profit is gained due to high prices of raw materials.

In the exhibitor’s area we will show other related devices and systems:

With the help of Liebherr LH 30 M, a mobile 30 ton truck, the carcass is loaded into the scrap press. The LH is equipped with a Zato Cayman 2, FCE30R scrap shears. This compact 3rd class scrap shear works with a power of 580 t. It perfectly suits for cutting large trucks and their frames.

ZATO especially designs and produces compatible shears for scrap and metal recycling with an installed weight of 1-9 tons. It is the market leader also for heavy-duty rotary shears, shredder systems, sorting systems and cleaning systems for scrap and metal processing. VENETO Schwenter represents ZATO and also sells M&J 4000 mobile shredder for wood, waste, aluminum and the like, which is on display here. In addition, VENETO Schwenter trades the whole range of equipment for recycling companies.

Finally, a magnet is used to pick up SkanCraft.

The company called Decker Containerbau, based in St. Wolfgang – 40 km from here in the heart of Bavaria, produces containers in all variations and designs that definitely meet high demands of most scrap yards.

07 Compacting

The compacting of car carcasses is the last step in the recycling process. The excavator is now loading the carcass into the Roter Recycling scrap baler RR6. The RR6 claims to be the fastest baler available on the market. It is driven by a 75kw diesel engine, but is also available with an electric motor (optional). The Roter company offers a stationary, semi-stationary or mobile version on a 3-axle trailer. A crane with a cabin can also be ordered as an option. The side flap works with 3 powerful hydraulic cylinders and around 280 bar pressure in the hydraulic system. Finally, a 60 x 90 cm bale is automatically ejected on the right side. These scrap bales are now sent to the shredder where they are processed into small chips before the raw materials are separated and melted down again.

Unlike classic electromechanical balers, it is equipped with a programmable logic controller and its own software, which makes its interface compatible with other machinery of the company and performs a careful and precise analysis of consumption variables in a real-time mode. Furthermore, in the event of failures and malfunctions (in the latter case it is enough to contact technical support directly by means of a special APP and a technician will immediately establish a connection to the baler to do the troubleshooting, identify the error and act accordingly) this baler is equipped with a remote video viewer that allows the user and technician to work in REAL TIME, eliminating the cost of sending technicians to the bailer’s location.

In addition, there is the SEDA AutoFlattener with a pressing force of 110 tons, which in one compact move crashes the car scrap and guarantees car carcasses flattened to a length of 3.8 m and a height of 35 cm.

References

Exhibiting Partners

Links

Reports:

Pictures:

Videos: