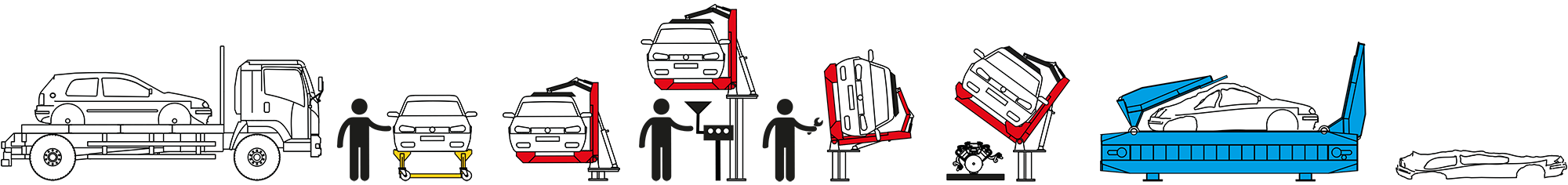

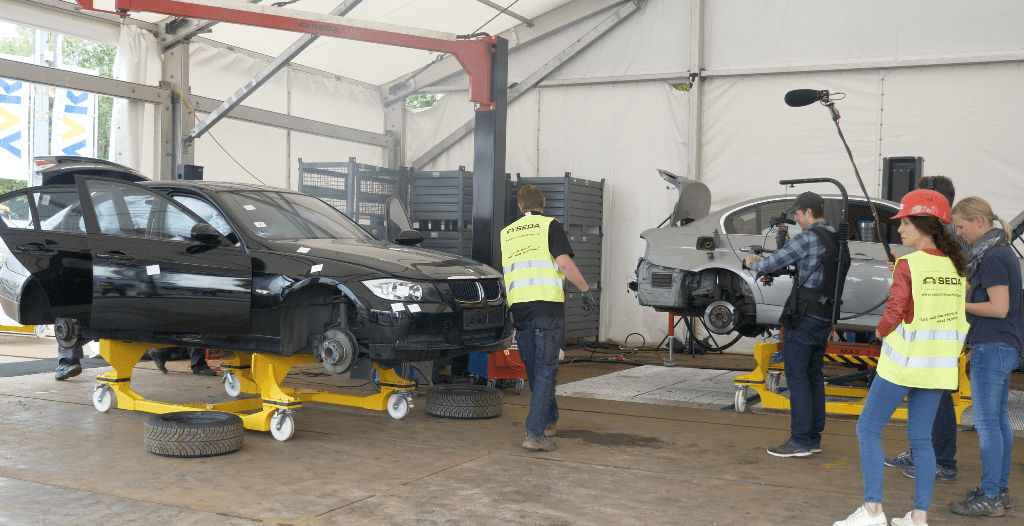

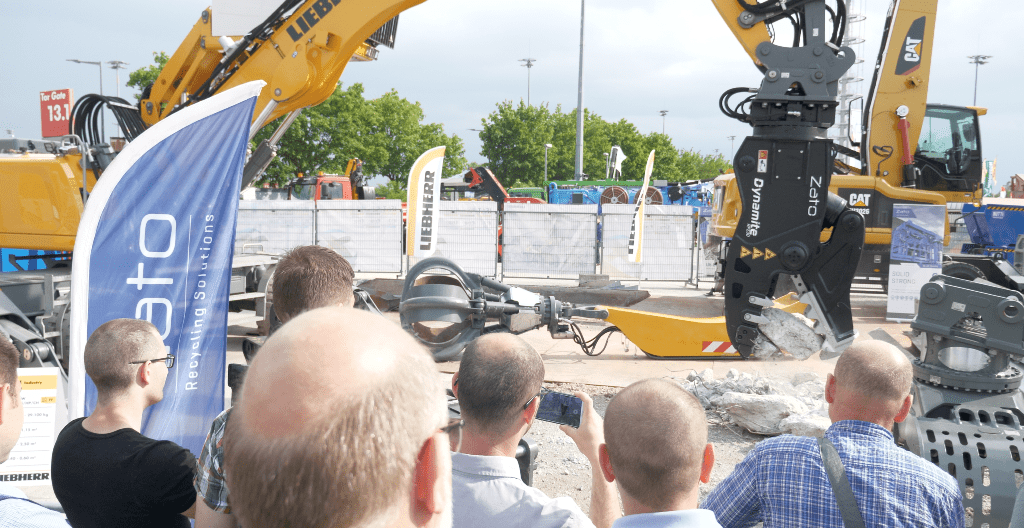

SEDA-Umwelttechnik GmbH and BDSV (federal union of German steel recycling and waste management companies) presented a car recycling live demonstration at the IFAT 2018 show in Munich/Germany. Visitors of the world’s leading trade fair for water, sewage, refuse and recycling had the chance to watch all steps of the ELV recycling process on 3.586 sqm exhibition stand four times a day. Industry professionals and of course the SEDA expert team answered many questions and showed new possibilities for recycling companies.

IFAT 2018

More than 141,000 expert visitors from more than 160 countries came to Munich between May 14 and 18, 2018 (2016: 136,885 visitors). Above all, this means a rise of IFAT’s internationality. The highest growth came from (in this order): Japan, Russia, Australia, China and Slovenia. In total, 3,305 exhibitors from 58 countries presented their products and innovations for the booming environmental industry.

More than 141,000 expert visitors from more than 160 countries came to Munich between May 14 and 18, 2018 (2016: 136,885 visitors). Above all, this means a rise of IFAT’s internationality. The highest growth came from (in this order): Japan, Russia, Australia, China and Slovenia. In total, 3,305 exhibitors from 58 countries presented their products and innovations for the booming environmental industry.

The next IFAT takes place in Munich from May 4 to 8, 2020.

More: www.ifat.de

IFAT car recycling video

IFAT Video (Long Version): Link

01 Storage

At the first station you can see the perfect storage solution for vehicles (storage rack). A compact storage of ELVs on a small footprint according to EU directives helps to guarantee order and cleanliness. A computerized warehouse management system allows a direct access to each individual vehicle.

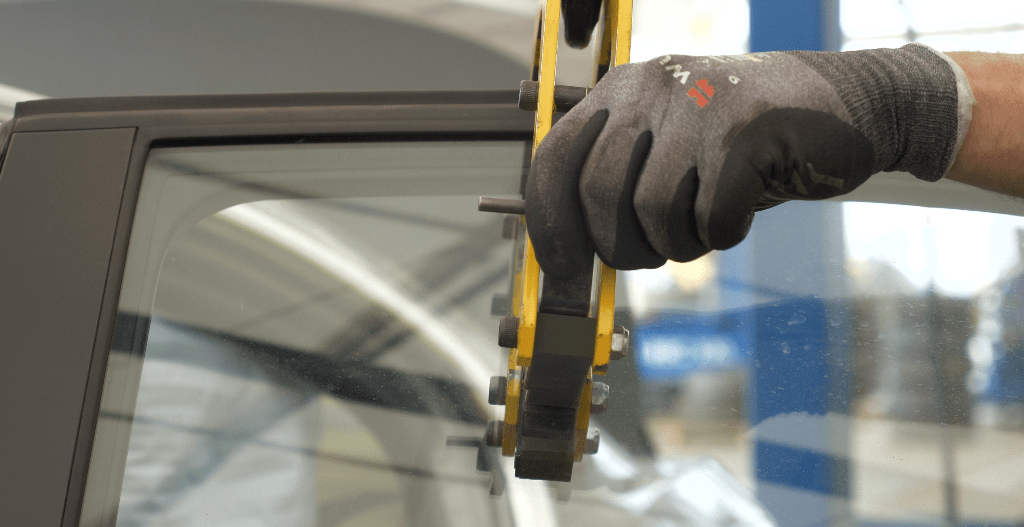

02 Preparation

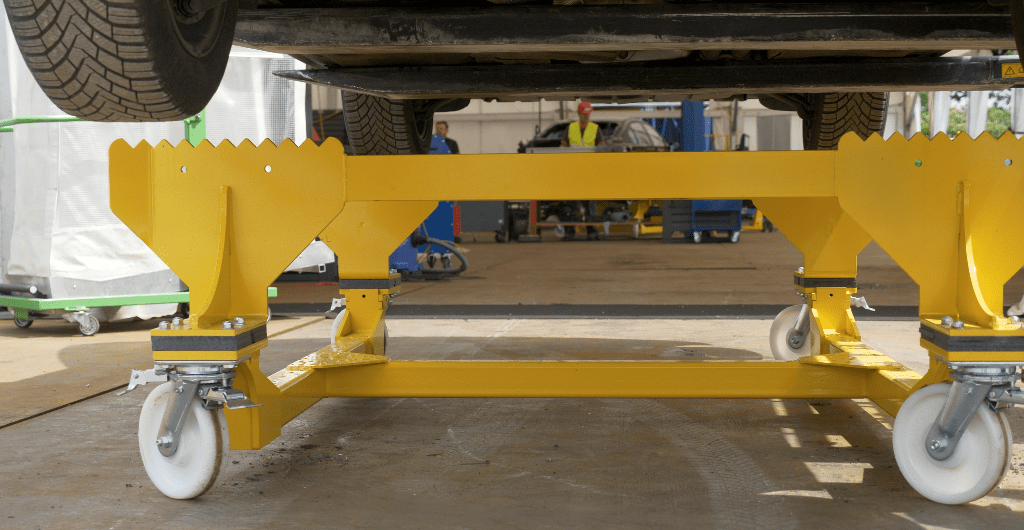

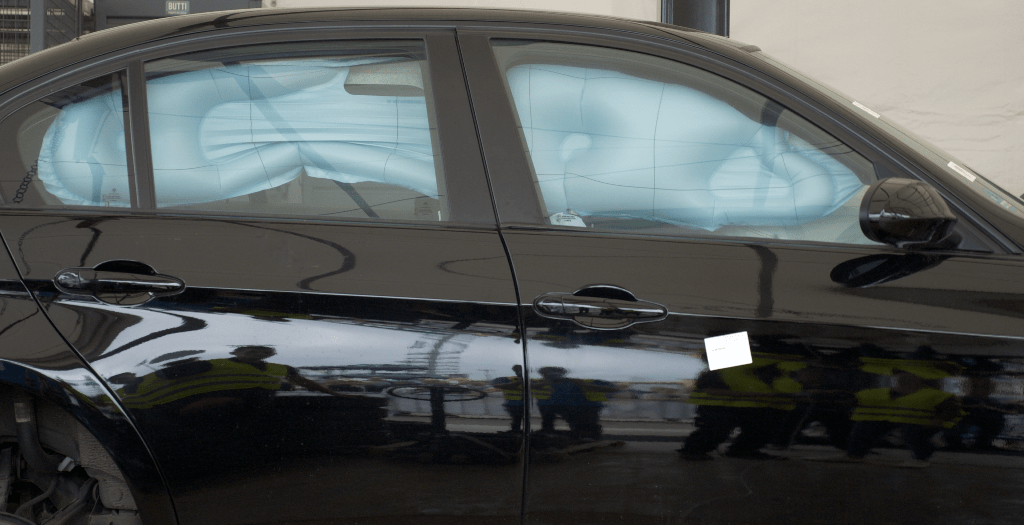

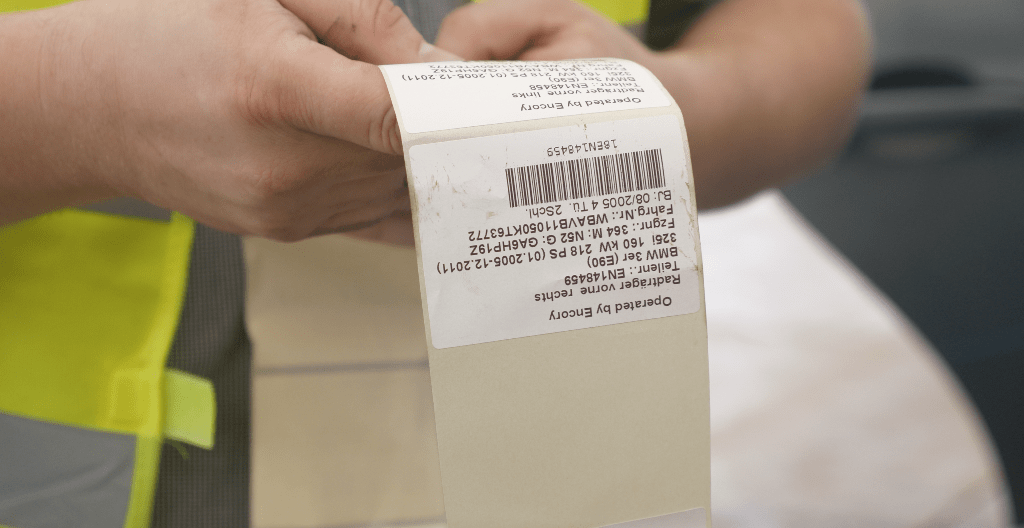

The second station includes the preparation of ELVs for an efficient processing. At first, the vehicle is placed on a trolley for a forklift-free use. Vehicle registration is recorded with the help of a computer software. After that battery and tyres are removed as well as air-conditioning gas. Finally pyrotechnic safety devices like airbags and belt tensioners are deployed and the glass is removed.

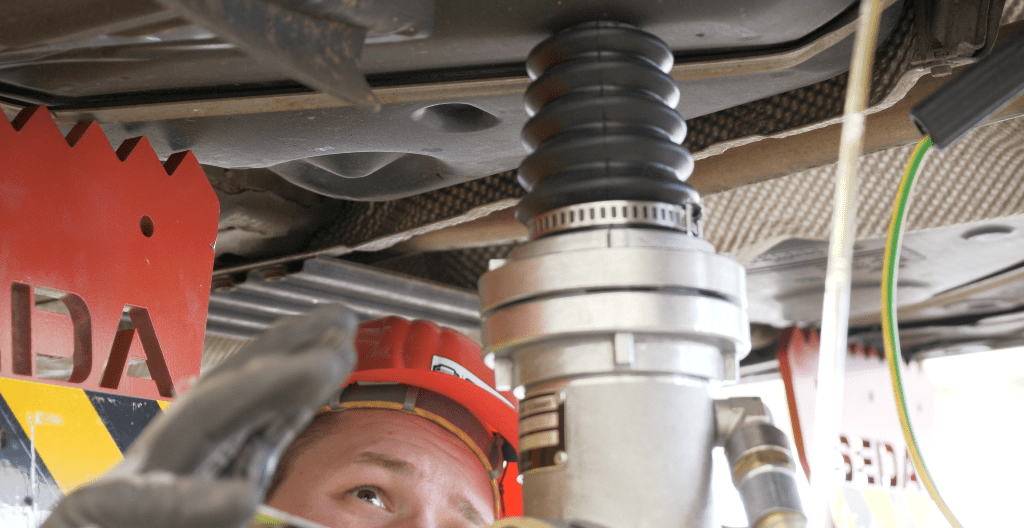

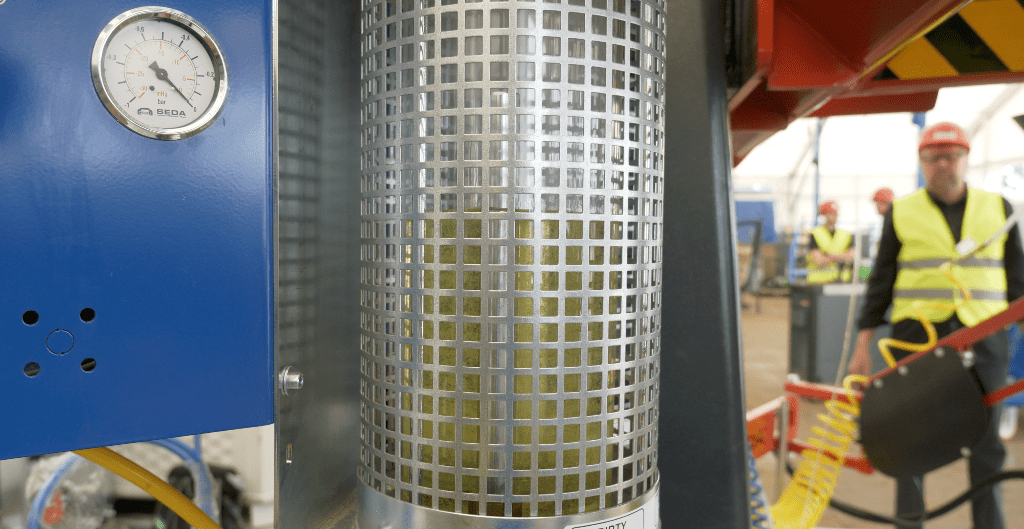

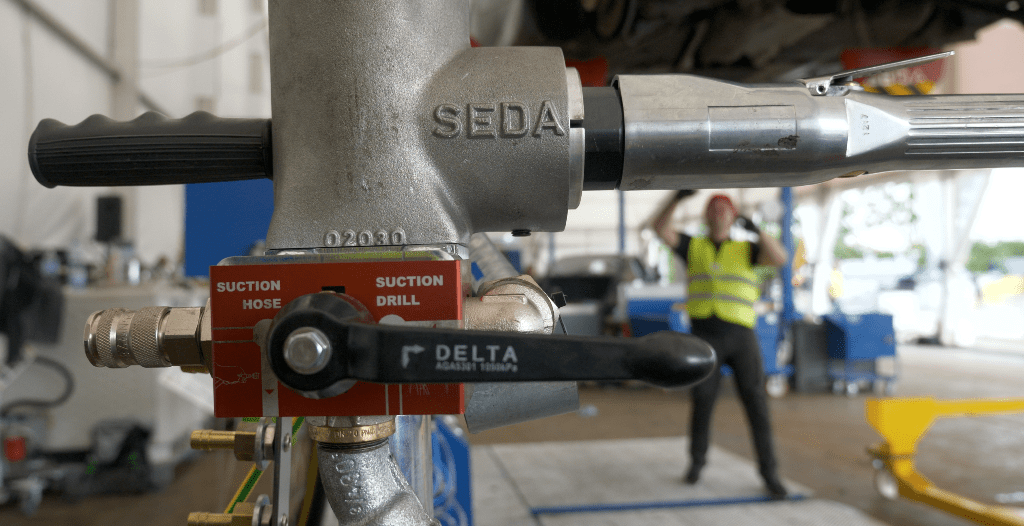

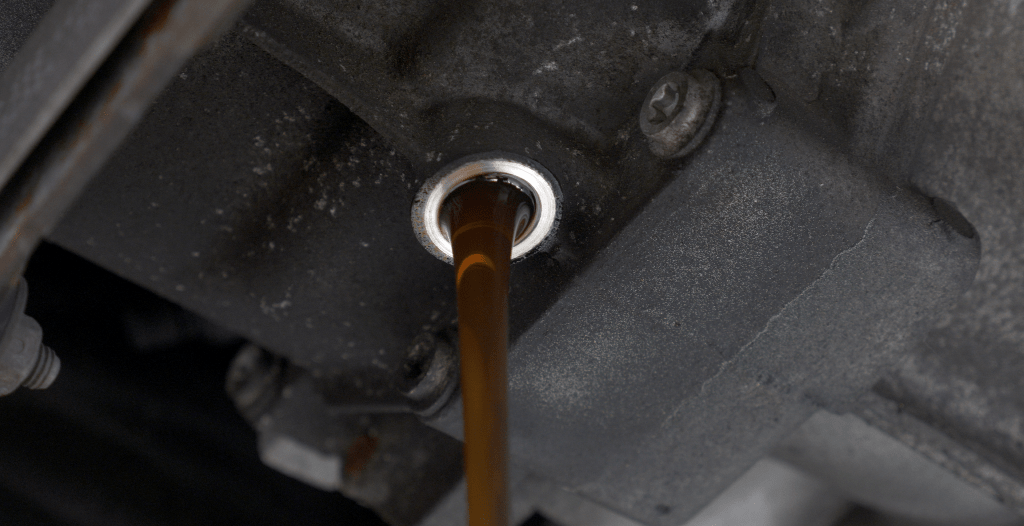

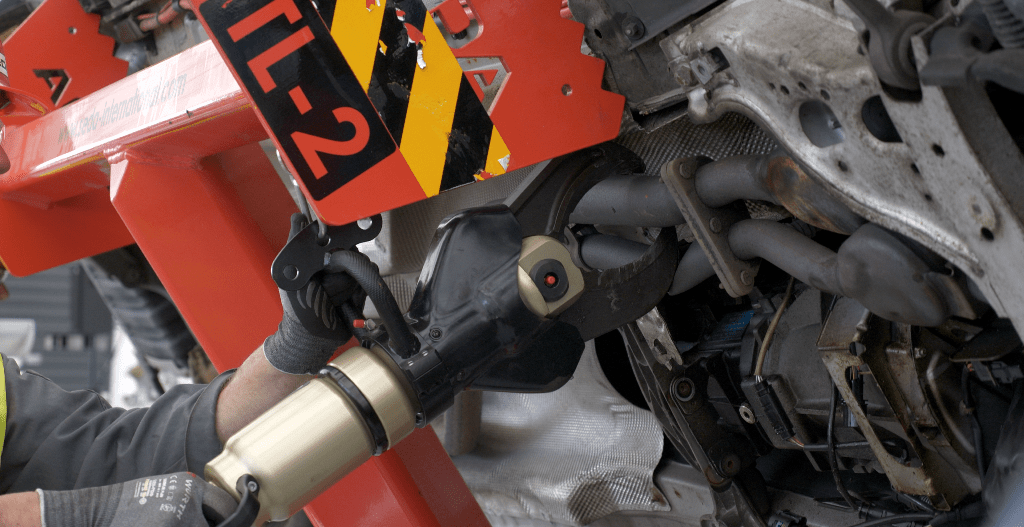

03 De-pollution

The third step is de-pollution which takes place at SEDA’s DrainLift Professional. This plug-in and play solution fulfills the highest EU directive standards. On average, an ELV contains 22 liters of harzardous liquids like petrol/diesel, coolant, brake fluid, engine oils, transmission oils, hydraulic oils and windshield washer fluid. With the help of SEDA equipment (like the famous TankDrillingMachine) these liquids can be removed efficiently and completely secure.

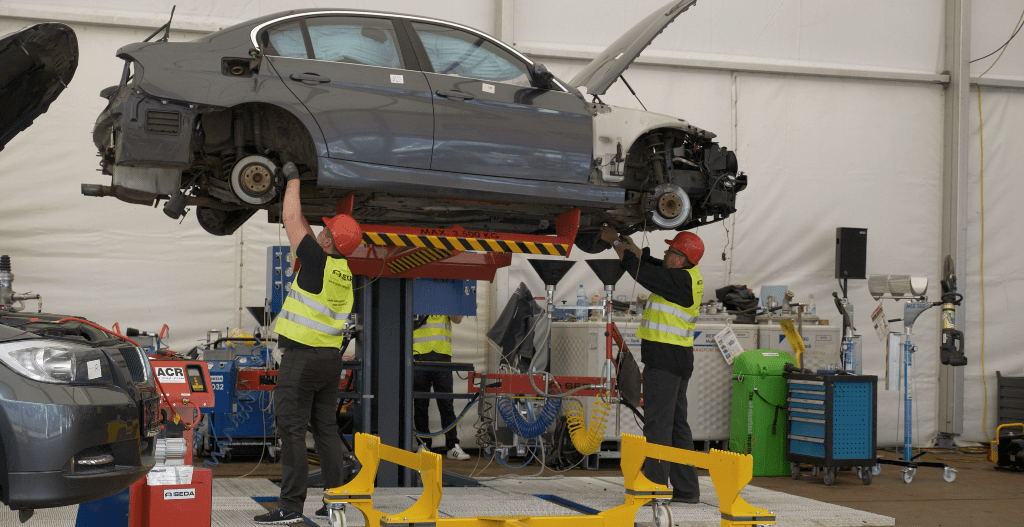

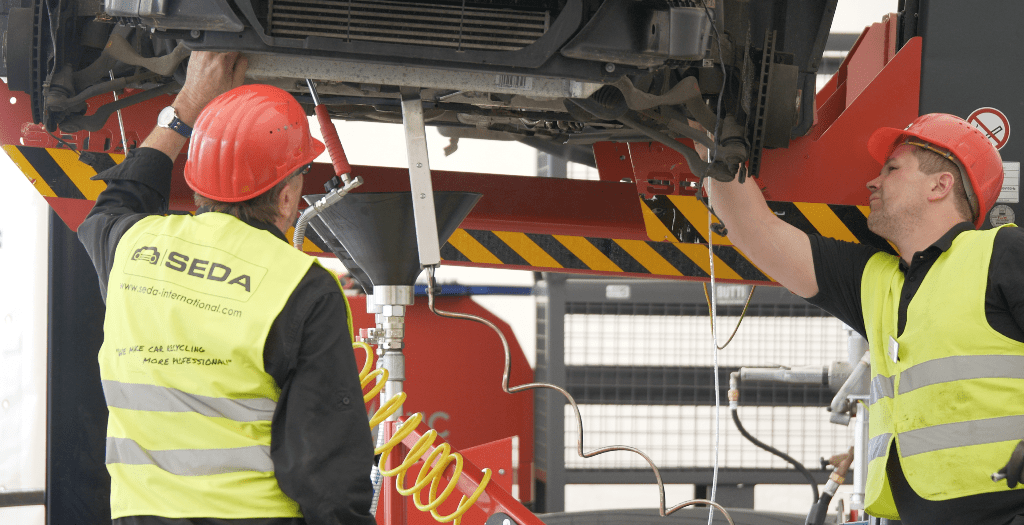

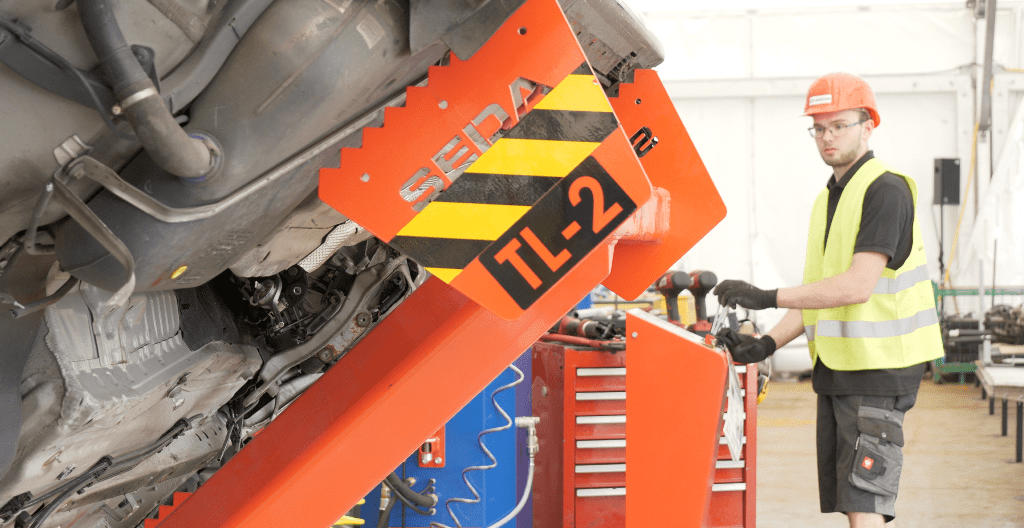

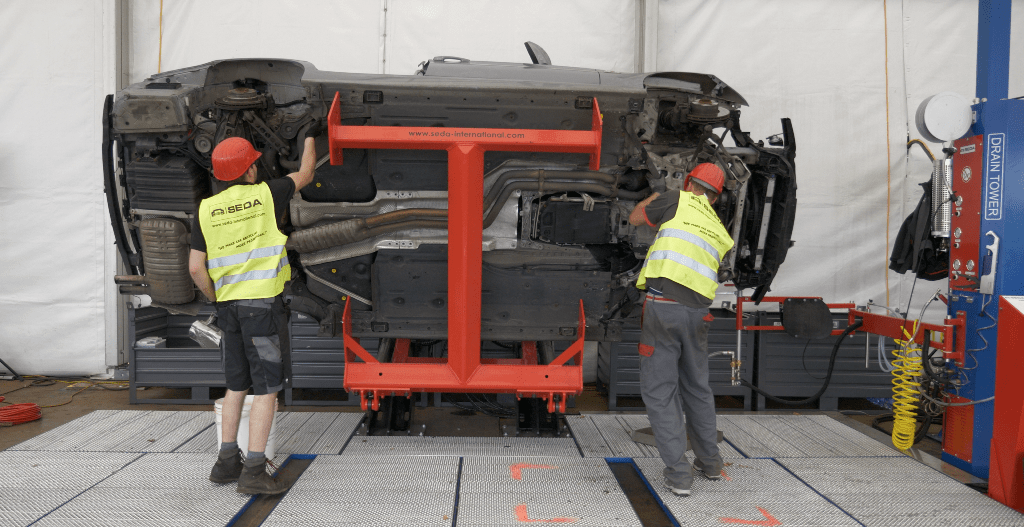

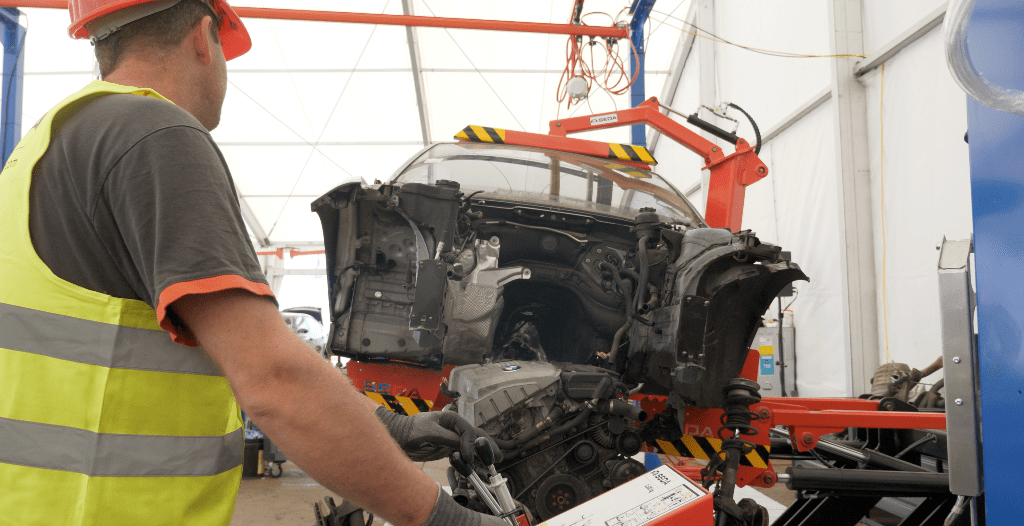

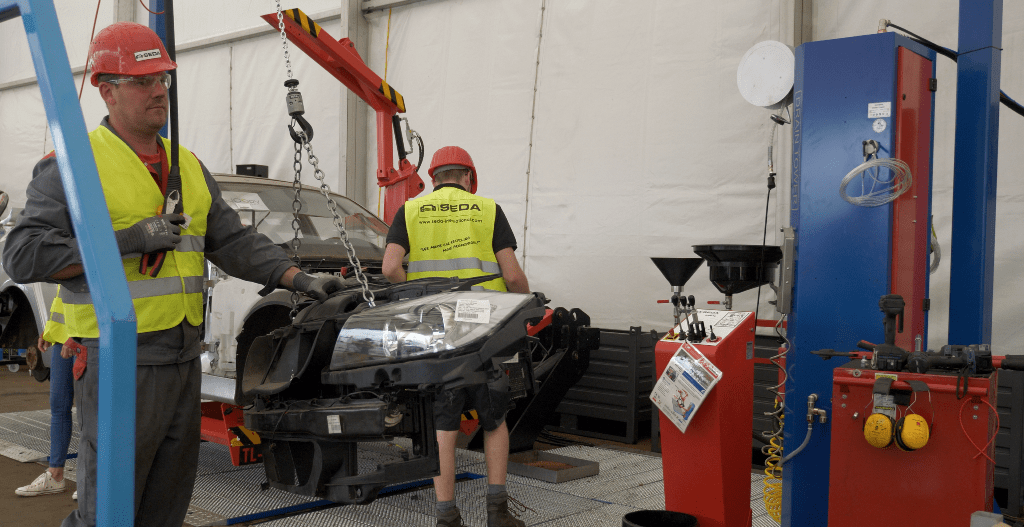

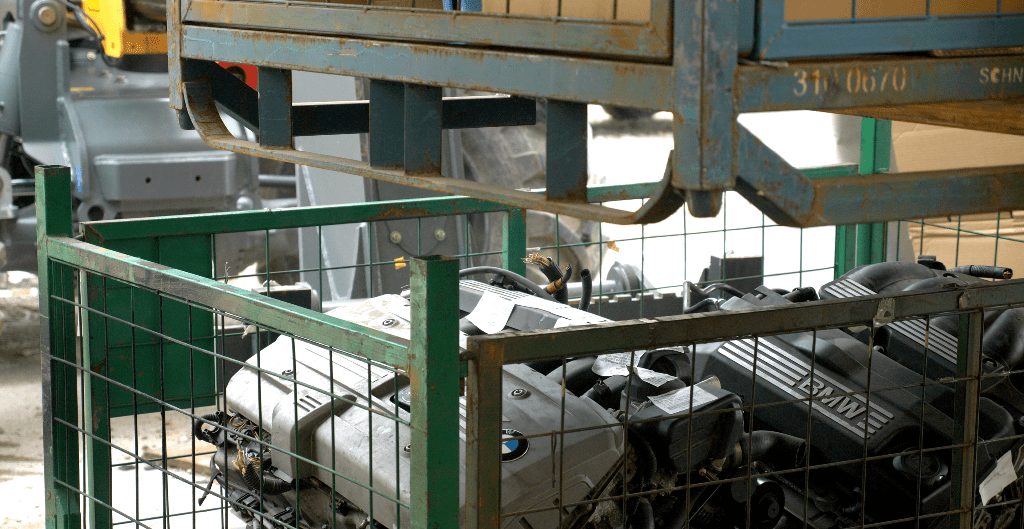

04 Dismantling

Station number 4 shows the dismantling of a cars by using the SEDA All-In-One Solution. Parts removal and de-pollution in one place – that’s revolutionary and makes this SEDA system unique. A special TiltingLift guarantees a simple and ergonomic work with its multi positioning. You move the car – not the worker. It’s possible to de-pollute and dismantle a complete ELV within 2 – 3 hours.

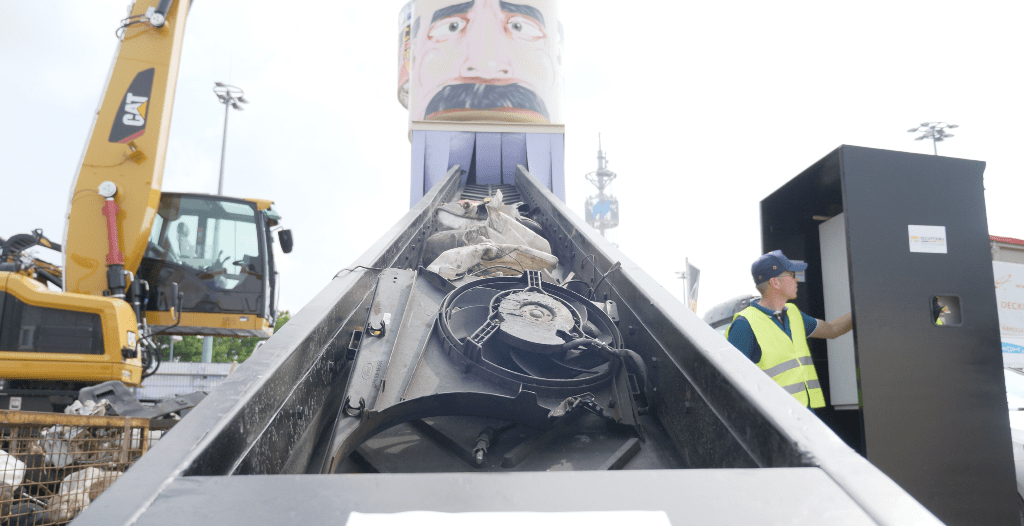

05 Reprocessing

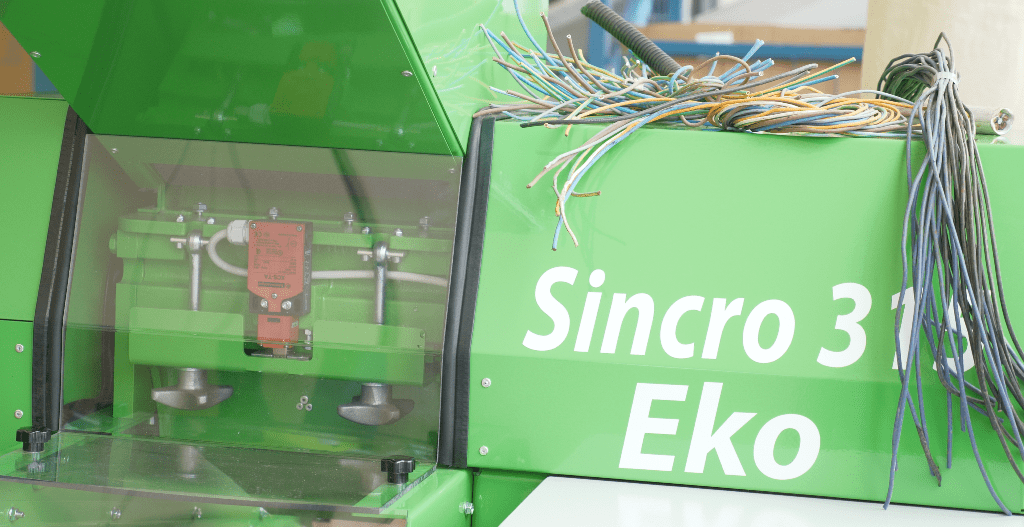

At the fifth station you can see the reprocessing. It includes a parts-cleaning table, a plastic shredders as well as the separation of cables and metals using the CableShredder.

Additional machinery of the reprocessing involves the mobile scrap shear of Zato, which fits perfectly together with the LH30M Industry Litronic of Liebherr, the UZ from Rekuperma, safety boxes for batteries, ForkliftBroom from staplerbesen.de, containers from Decker and equipment von SW.Rent.

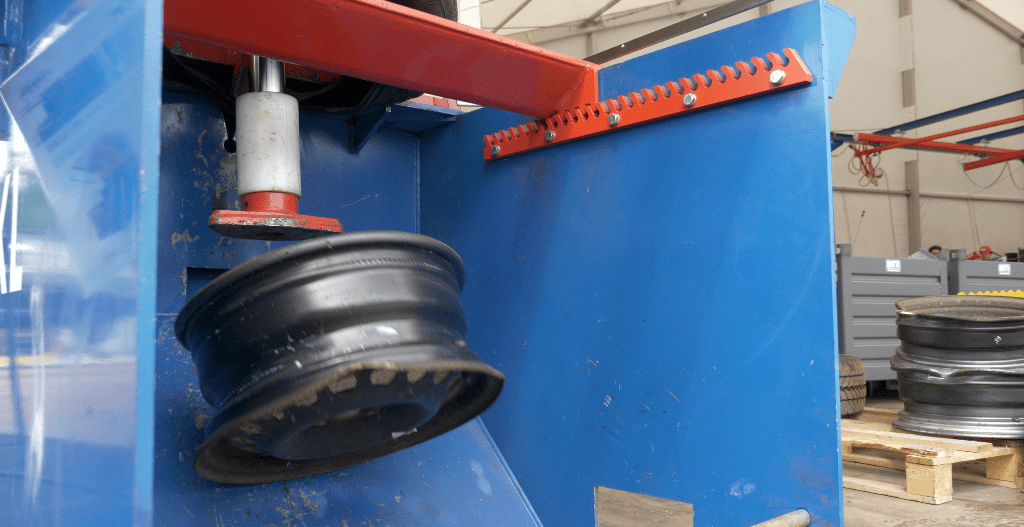

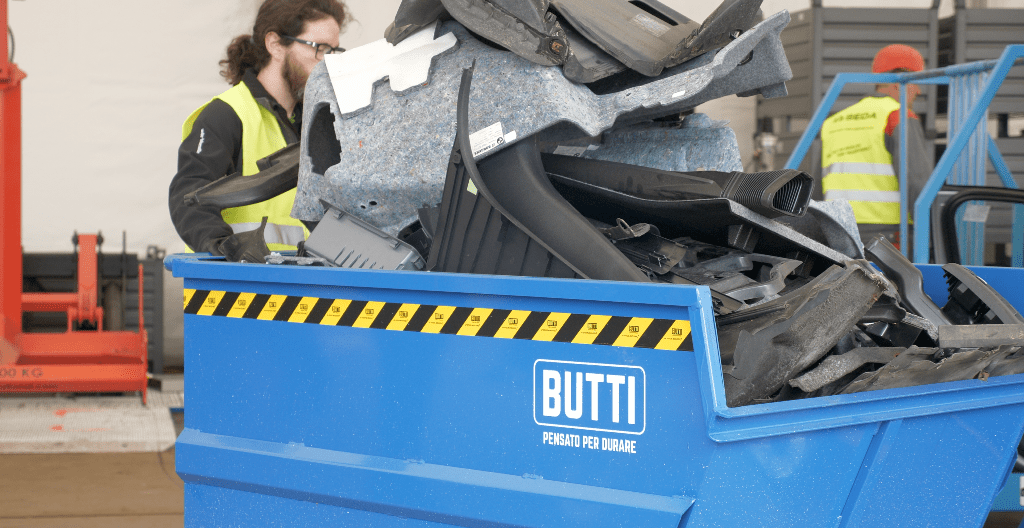

06 Compression

The compression of car bodies completes the recycling process shown at the IFAT 2016. There are two options. On the one hand the SEDA CarFlattener, that squeezes wrecked cars to a length of 3.8 m and a height of 35 cm in one operation with a press force of 110 tons. It ensures a flat car body. Secondly, the CarPress ejects scrap packages. The compressed bales have a size of 800 x 1200 mm.

References

List of exhibitors and partners

Links

Berichte:

Pictures:

Videos: